Agitator, Industrial Agitator, Manufacturers, Suppliers, Exporters in India, Pune

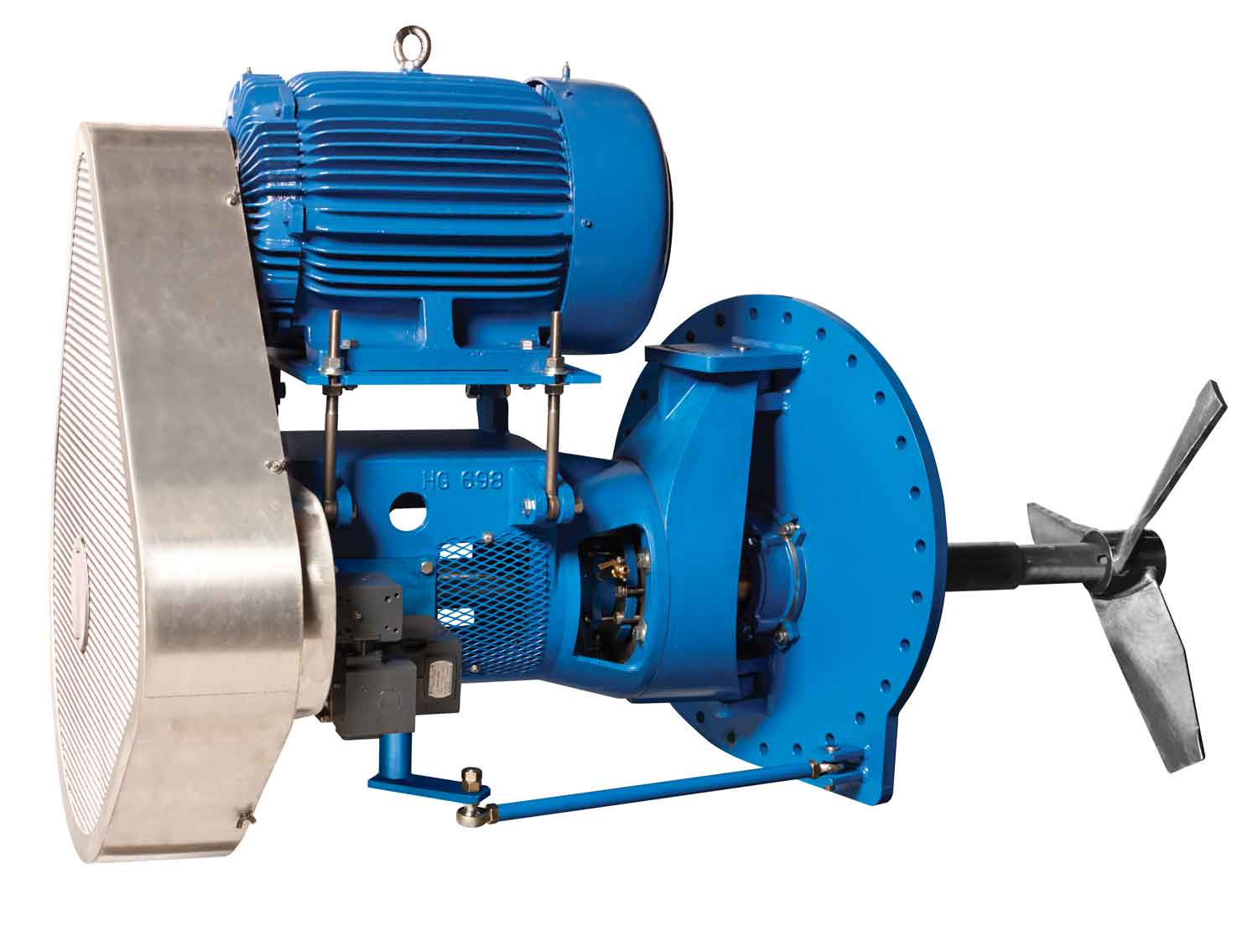

The agitator is a piece of technical machinery used to mix liquids uniformly. To prevent any unexpected casualties or challenging factors this apparatus makes sure that a uniform mixing of solutions is carried out. There is no better website than SPM Process System if you're searching to buy an agitator online. SPM Process System is an India digital platform that enables suppliers to connect with numerous trustworthy manufacturers and suppliers in India, Pune.We manufacturers, suppliers, exporters of agitators. To mix or stir the substance in different tanks, portable stirrers and agitators are utilized.

Agitators are widely used in the chemical, pharmaceutical, food, grease, metal extraction, paint, adhesive, water, and cosmetic industries for a variety of purposes.

SPM Process System is a known manufacturer and supplier of Agitators in India, Pune, which is provided as per the various requirements of clients. We manufacture products using high-quality steel and cutting-edge machinery, and customers can get them from us at costs that are among the most affordable in the marketplace.