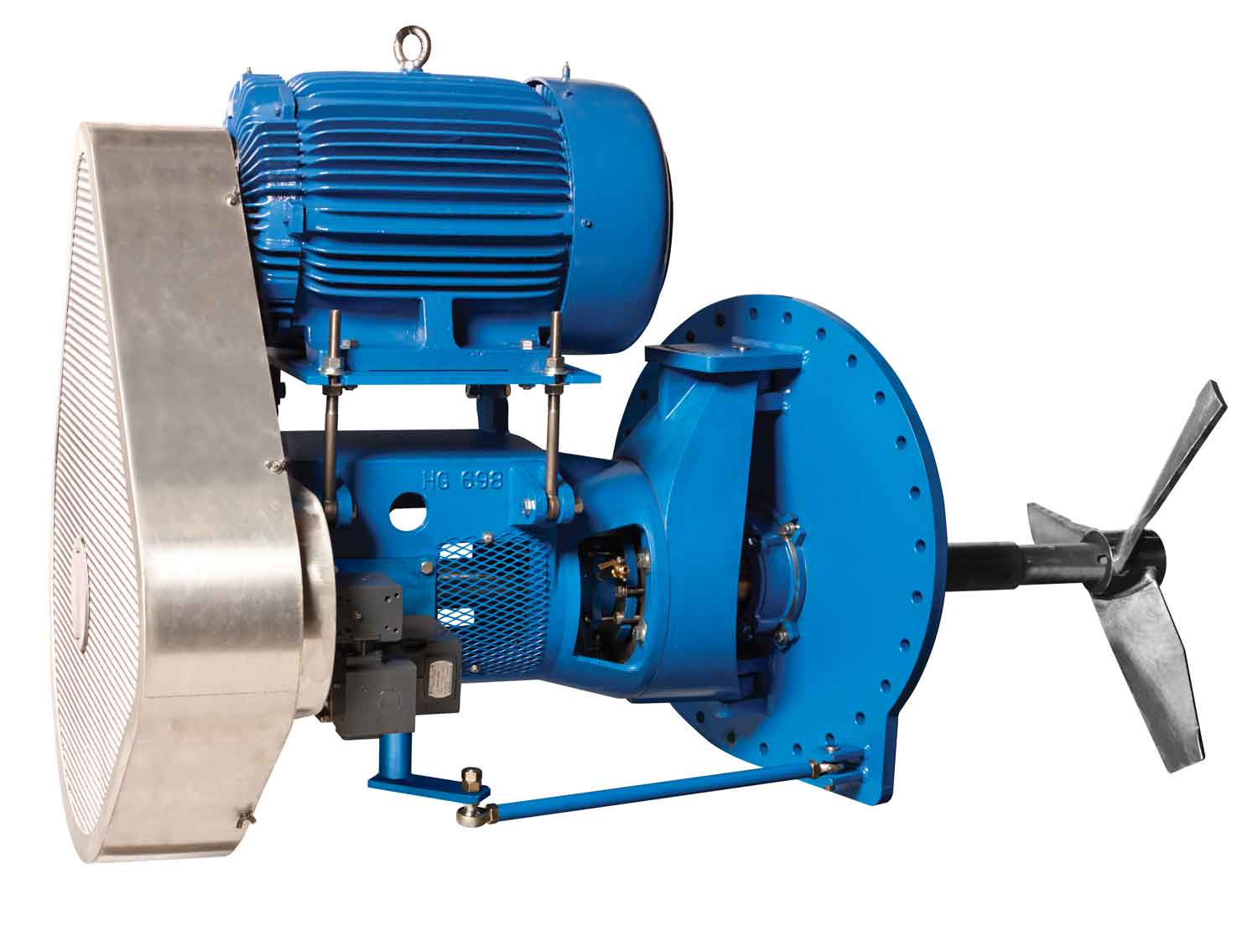

Bottom Entry Magnetic Mixers

SPM magnetic drive agitators are highly hygienic solution for the applications of dispersion, dissolution, homogenization and mixing in the pharmaceutical, biotechnological and food-processing industries.

Due to the magnetic coupling they are especially useful because they avoid any possible contact of the product with the atmosphere.

Mixer Model :SMD-100

Speed Range : 100 – 2850 RPM

Material :Stainless Steel (Other material Available)

Electrical Characteristics :50Hz 415V 3Phase / 60Hz 460V 3Phase

Design And Features

ZERO LEAKAGE Design

Designed for cleaning and sterilization.

Bottom mounted. Excellent for

suspensions

Non Contaminating Mixing

SPM Process Systems is the leading Magnetic Mixers manufacturer, supplier, and exporter in India. Our mixers are installed at the bottom of the tank. The products we offer are manufactured by experienced professionals using the highest quality components and advanced technology.

To ensure quality, these liquid section magnetic stirrers undergo rigorous testing on various parameters. In accordance with international standards, we offer a full range of products in different models and technical specifications to meet the evolving needs of our customers.

Description

The magnetic mixers offered are made of 304/316 grade stainless steel and are used for uniform mixing of liquid-based chemicals. Available in a variety of mixing capacities and design-based options, our mixing solutions feature advanced magnetic drives, stirring shafts, mechanical seals and stainless steel wetted parts.

Motors with these mixed solutions will never burst. Our magnetic mixers are quality verified based on mixing performance, operating speed, lifespan, construction, lifespan, handling, load capacity and more.

Exclusive Features

- Hermetically sealed design: The driving force is transmitted contactless via the magnetic field. The risk of contamination is therefore very low.

- Performance and high stability: Proven magnetic coupling technology ensures very high torque transmission.

- Standard solutions and customized designs: We offer an established product portfolio and custom-made solutions.

- Easy installation and maintenance: Our experts offer a comprehensive service range of magnetic stirrers.

- Easy cleaning: The open design allows for superior CIP and SIP functionality.