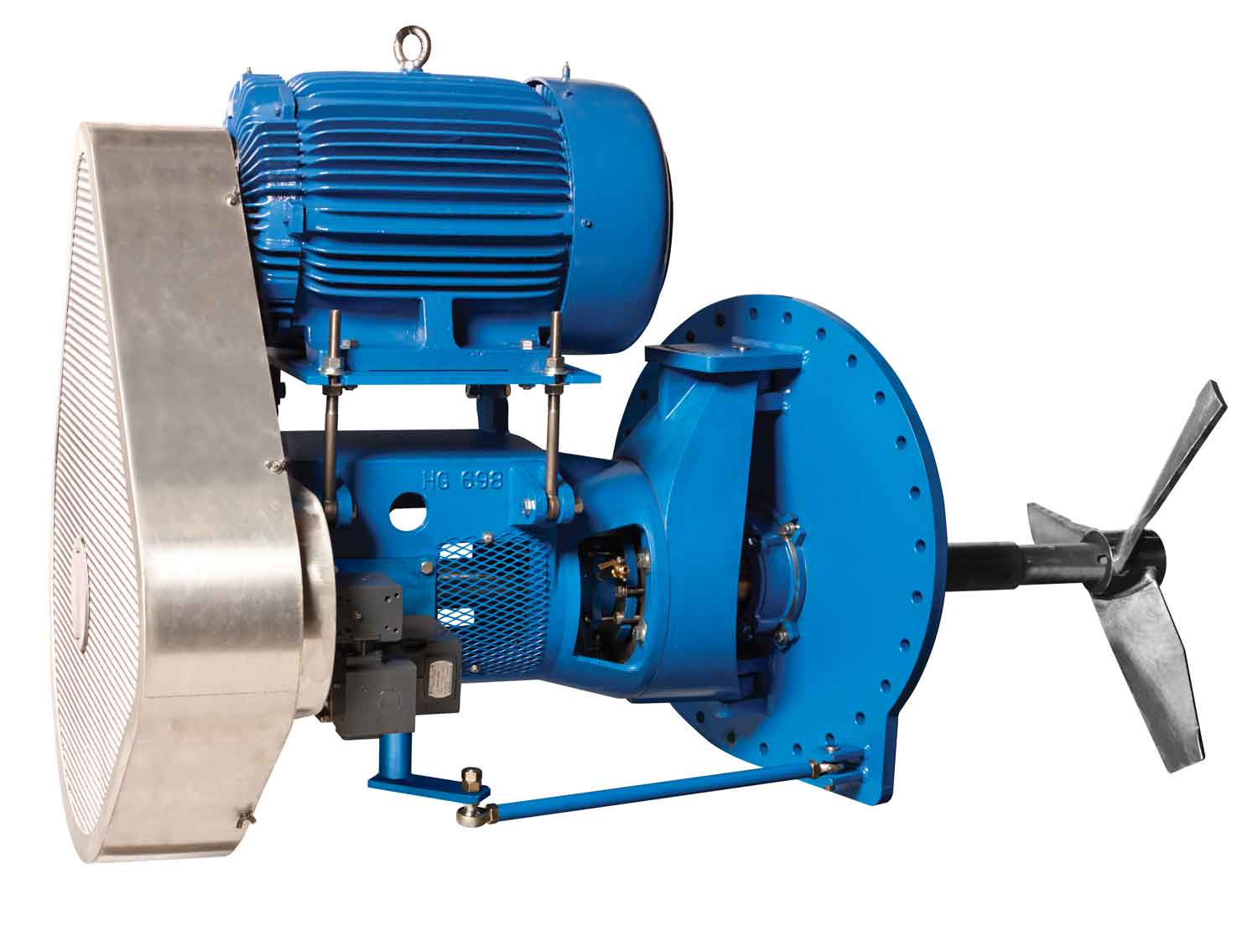

Top Entry Agitator

SPM Top entry agitators are designed for a wide range of service in the chemical, pharmaceutical, mineral, water and wastewater, food and beverage, flue gas desulfurization, power and other general process industries. The agitators feature a new, high-efficiency gearbox designed specifically for agitator service. Models are available in right angle and parallel shaft configurations to meet specific application requirements from critical chemical reactor systems to routine storage.

Mixer Model :STE-100

Speed Range :~25 – 2850 RPM

Material :Stainless Steel (Other material Available)

Electrical Characteristics :50Hz 415V 3Phase / 60Hz 460V 3Phase

Impeller Type :Hydrofoil / Propeller / Turbine /Disperser Blade /Anchor / Helix etc as per process requirement.