Mixer/Industrial Mixer Manufacturers, Suppliers, Exporters in India, Pune

Welcome to SPM Process Systems Mixer/industrial mixer manufacturers, suppliers, exporters in India,Pune. An industrial mixer is any piece of equipment used in bulk processing that is designed to combine different components to produce a uniform final product. Usually found in food processors and in laboratories dealing with chemicals and pharmaceuticals.

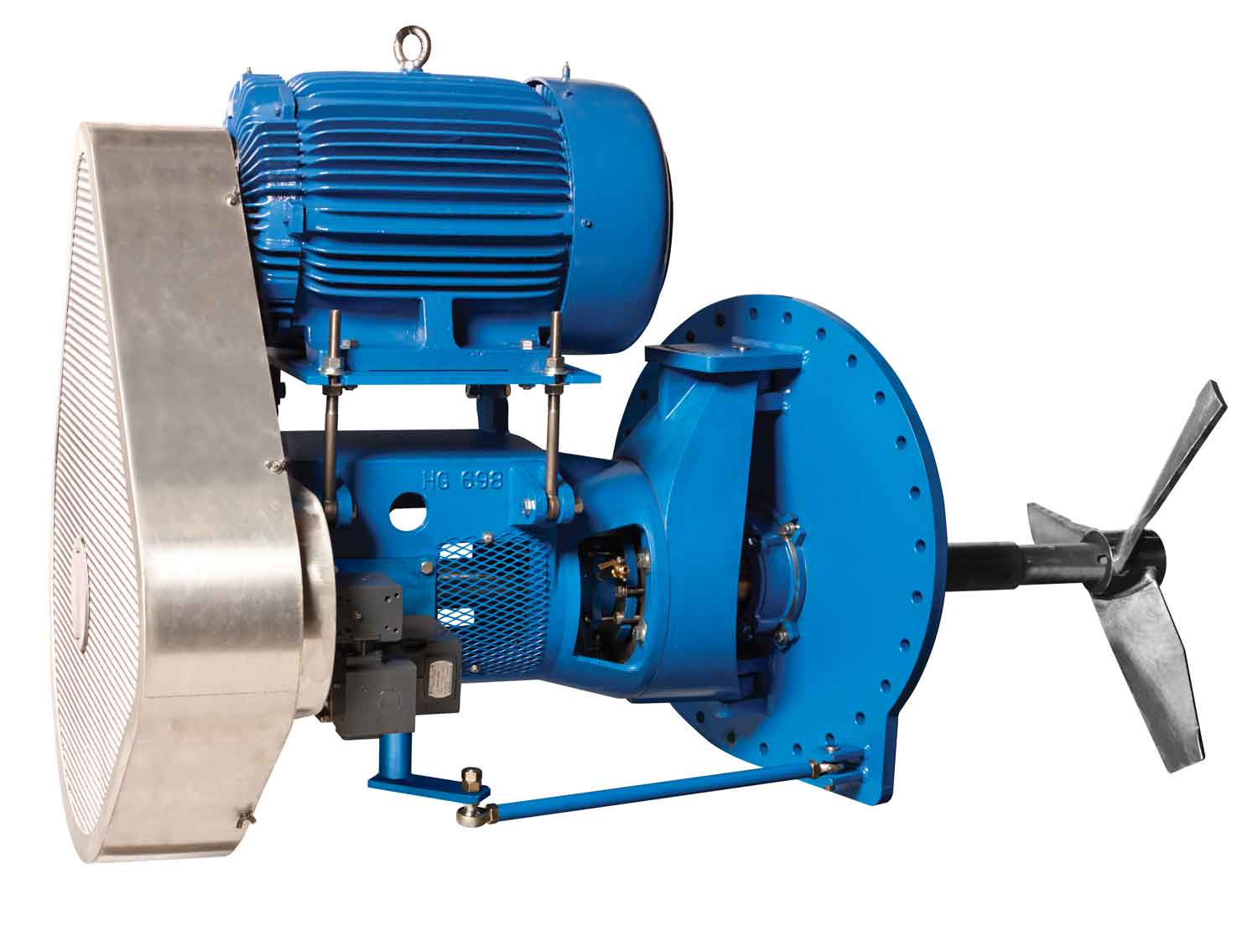

At SPM Process System, we take pride in offering high-quality and cutting-edge mixers/industrial mixers manufacturers in india for a wide range of industrial applications. With our state-of-the-art technology and expertise, we deliver reliable and efficient mixing solutions that meet the diverse needs of our customers.

The SPM Process System mixer offers excellent blending, shearing, and dispersing capabilities, making it ideal for blending and dispersing materials in solid-to-solid, solid-to-liquid, and liquid-to-liquid applications. The majority of industrial mixers utilized in this field from Pune, India.

Mixer/industrial mixer in India manufacturers also provide a wide range of products, like magnetic mixers, rotor stator mixer, stirrer, homogenizers, Industrial Blender, Liquid Mixers, Static Mixers, Mixer machine, Plough Shear Mixer, Industrial Chemical Mixer and Inline Static Mixer.