Stirrer Manufacturers, Suppliers, Exporters in India,Pune|Industrial Stirrer Manufacturers in India

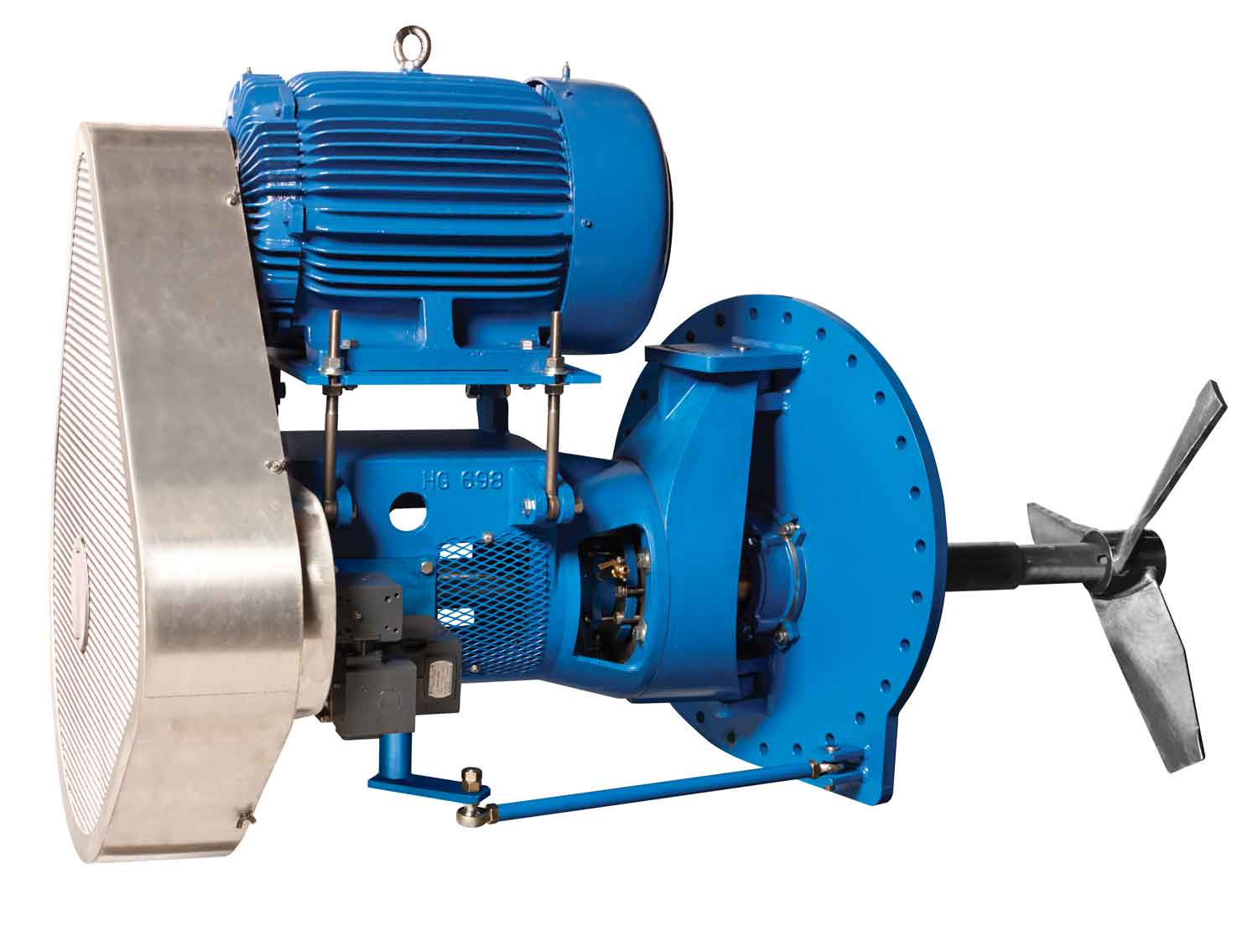

SPM Process Systems are a leading manufacturers, suppliers, exporters of stirrer in Pune, India. Laboratory, high speed, lab stirrer machine, mechanical overhead, multi position magnetic stirrer, drum and laboratory direct drive stirrer. It basically consist of the main body, chuck, stainless blade propeller, and stand. Stirrer manufacturers in India, Pune, also known as mixing paddles or agitators, are essential equipment used in various industries for mixing, blending, and stirring applications.

Thin liquids to thick pastes, industrial stirrer can handle a wide range of viscosities and consistencies. Stirrer manufacturers, suppliers based in India Pune are essential to guaranteeing quality, consistency, and uniformity in the manufacturing process, assisting businesses in reaching their production targets quickly and effectively.